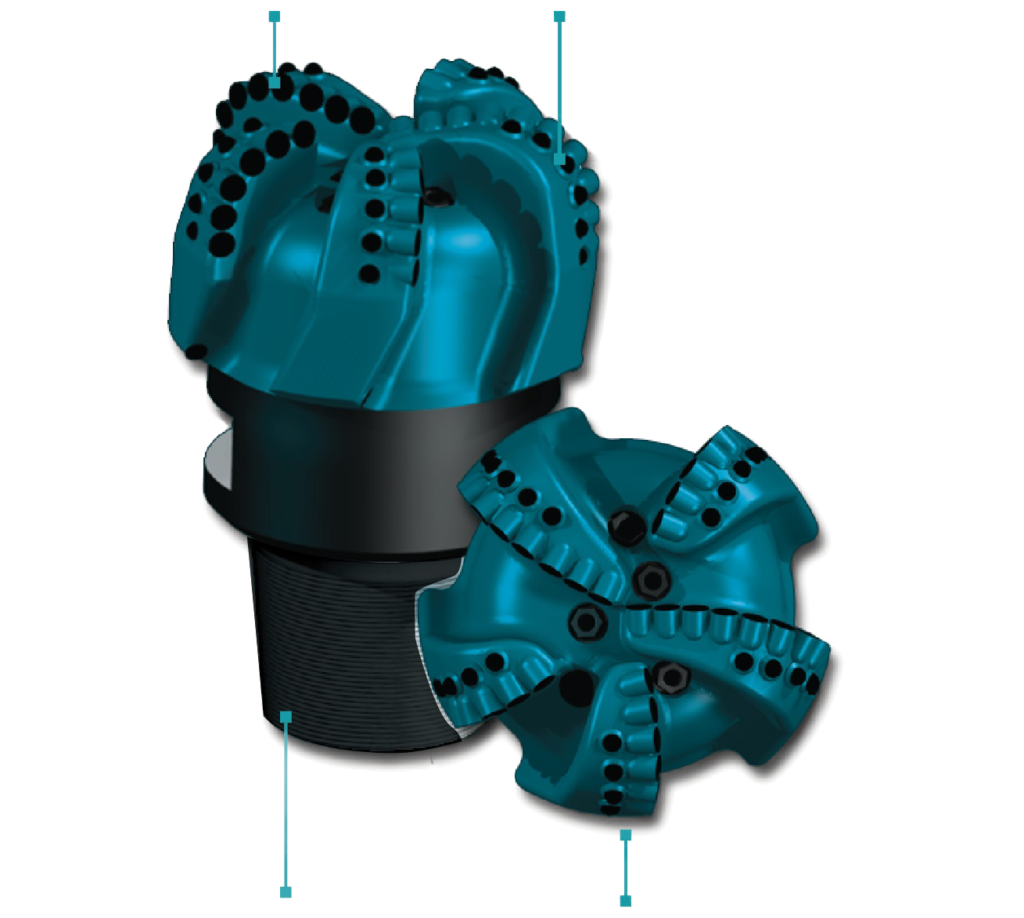

Premiun PDC Cutters

PDC Balanced for mechanical and abrasion resistance to increase bit life and ROP

Bit Stability

Ultra low inbalance force and shock reducers to increase bit life and ROP

Ultra Gauge Protection

To increase the bit life.

High Face Volume

To increase anability to avoid balling and re-drilling cuttings.

Fixed Cutter PDC Bits

Longer bit life, improved performance

With operators drilling to ever-greater depths in more challenging well environments, today’s drill bit technologies must deliver high rates of penetration; high-quality boreholes and cost-effective operation. Orion’s unique, reliable and practical drilling bit products are engineered to enable business partners to drill further, faster and with greater precision.

Drilling Further, Faster

- Our focus is application driven, getting the right product to the right place

- Premium PDC cutter technology

- Wide range of cutting structure reinforcement

- Bit body design defined to optimize the bit cutting efficiency, durability directional & dynamic response

.