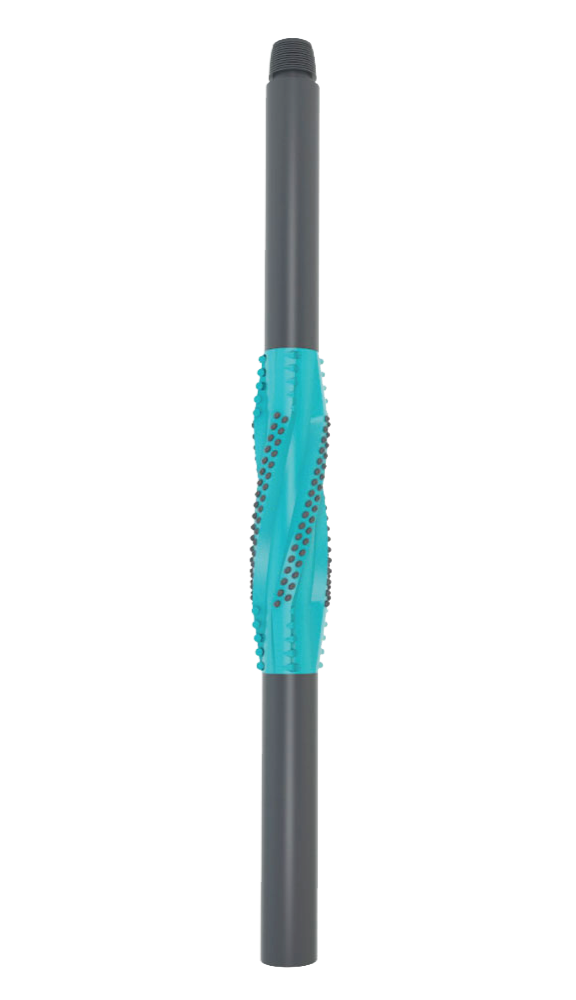

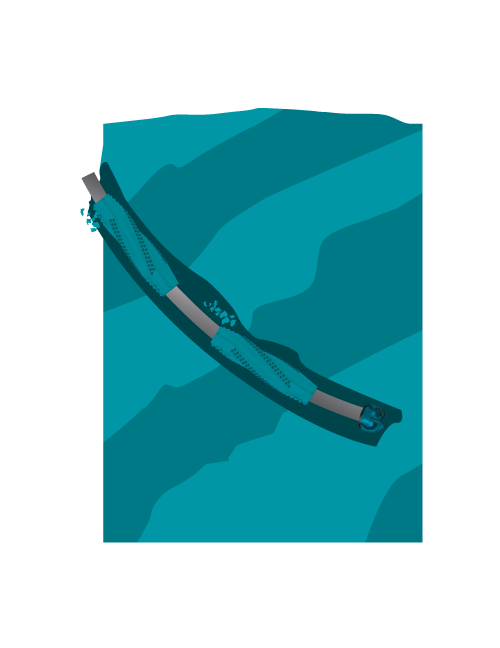

PDC SUPER REAMER

(Concentric)

PDC SuperReamer is a PDC blade reamer, with an optimized blade configuration to improve wellbone quality, reduce drilling NPT, eliminate dedicated reaming trips and avoid stuck pipe.

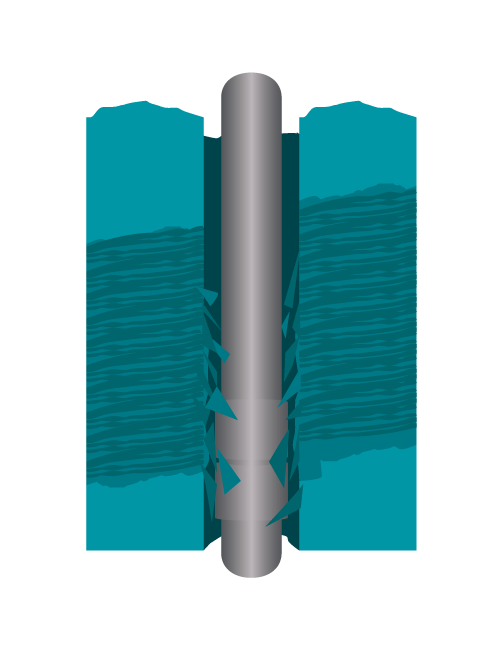

The PDC SuperReamer force balanced bi-directional cutting structure tool substantially improve the weight transfer to the bit of any conventional BHA. With the appropiate hydraulic program, PDC SuperReamer BHA will consistenly dill ahead at higher ROP in the tightest wellbores.

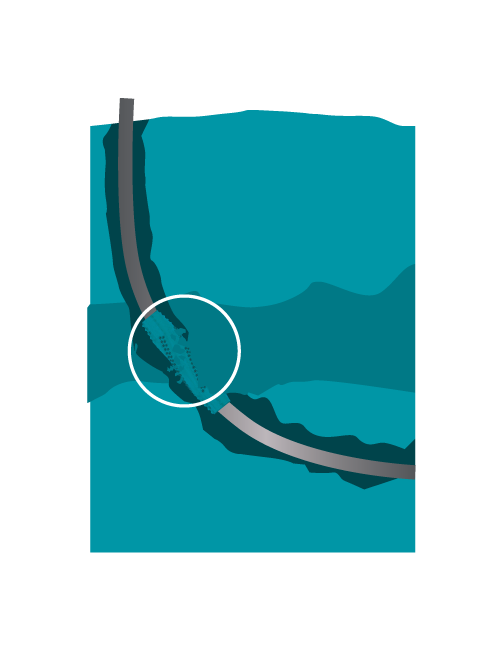

The PDC SuperReamer’s capability of constructing clean and in-gauge wellbores while drilling, mitigates the persistent risks of stuck pipe when rotating out of otherwise tight and highly restrictive holes.

APPLICATION

- Leading edges are enhanced with PDC cutters.

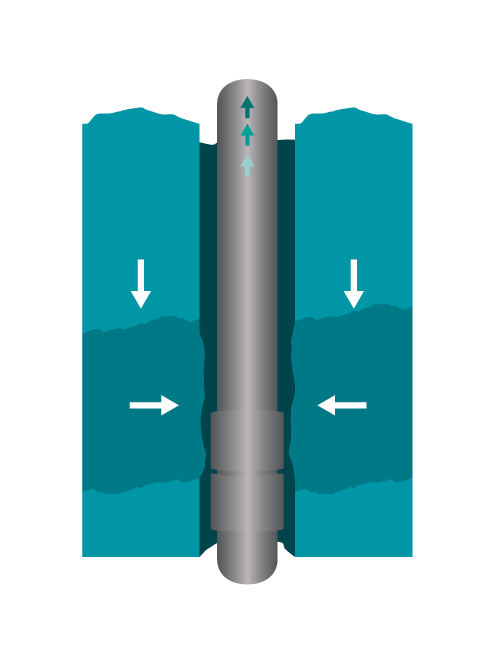

- Allows re-opening holes to avoid stuck pipe

- situation during POOH.

- Improves hole gauge and shape

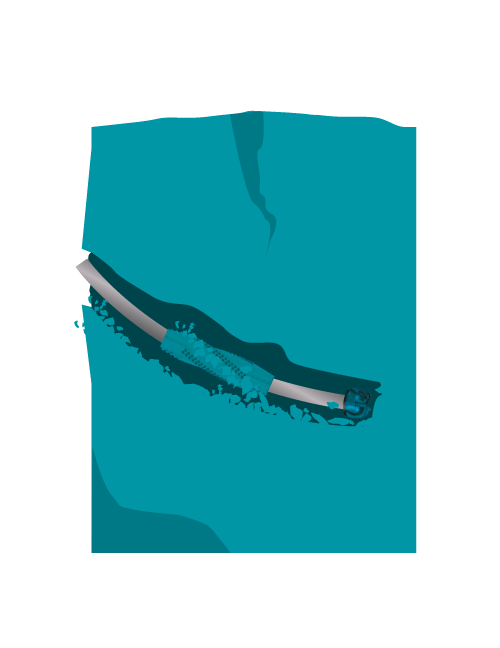

- Fits both vertical and directional drilling

Feautures

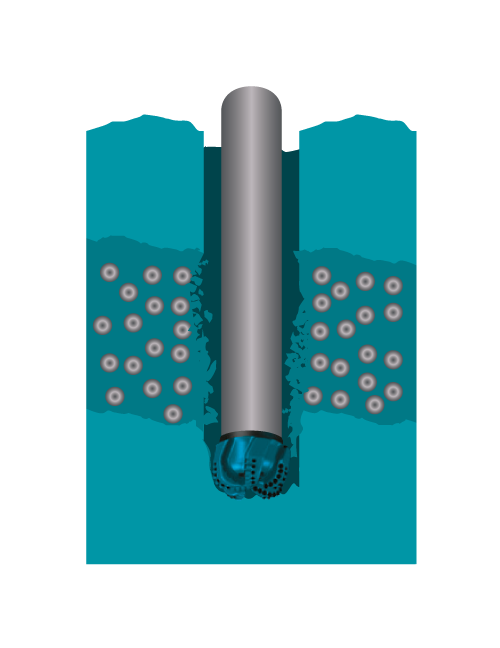

Symmetric cutter distribution for balanced drilling & reduced vibrations.

Optimized rake angle and side rake angle for max cutting efficiency.

Optimized TCI distribution for reamed surface uniformity and reduced insert wear.

Chamfered blade design for proper PDC cooling through mud circulation.

Optimized mud-ways shape and area to minimize balling potential.

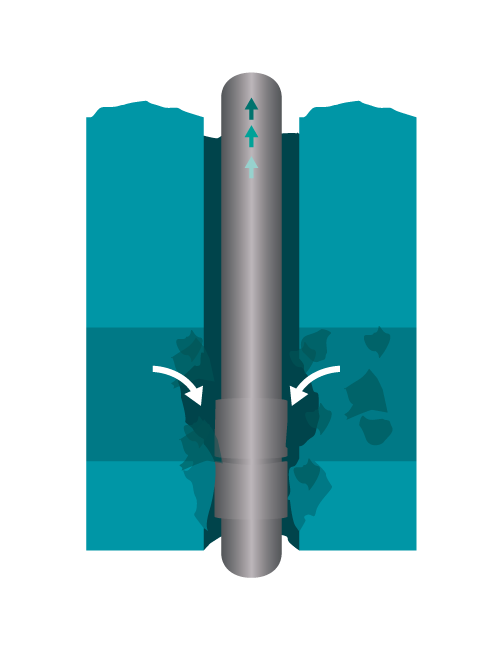

The PDC Reamer allows to re-opening the hole during tripping out minimizing stuck pipe issues. Improves hole gaguge and shape for vertical and directional drilling.

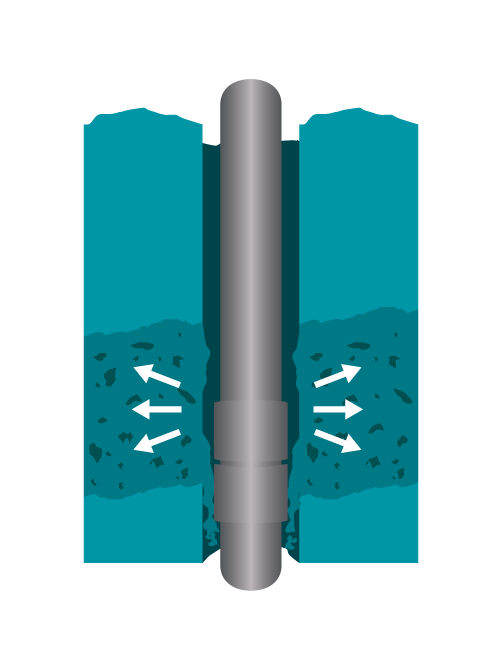

Reactive Formations

Mobile Formations

Faulted Formations

Unconsolidated Formations

Over-Pressured Formations

Hole Cleaning

Key Seating

Ledges and Doglegs

BENEFITS

- Ensure getting completition equipment to TD.

- Minimize NPT and time spent on wellbore conditioning.

- Faster casing running speeds, less time on location.

- Faster tripping speeds & more time tripping on elevators results in less time on location.

- Reduce BHA damage due to excesive vibration.

- Less NPT & lower damage fees.

- Longer bit and BHA runs resulting in less NPT.

- Less cost per well as result of higher ROPs.

- Faster trips. Tripping and tripping out, lower NPT and less equipment damage.